Book Appointment Now

“Breakthrough technology in trauma screw design, featuring cutting-edge non-locking and locking screws, has been patented in the USA, Europe, and India.”

How is the New Screw Design Minimizing Complications and Optimizing Patient Recovery — and Why Should Surgeons Choose Our Advanced MS Screws for Effective Fracture Treatment?

- New Design screws are easy to remove from any bone plate than old design.

- Dual Screw Driver Design: Only patented design Non-Locking and Locking Screw in the world that will accept 2 screw drivers. If one screw driver fails in the surgery , immediately 2 screw driver can be used to complete the surgery.

- Improved head rounding problem: Especially use 3.5mm, 2.7mm MS Screws and plates where ever it is required as chances of 3.5mm, 2.7mm Titanium screws failure is much more with old design screws.

- Pediatric Patients Advantage: For children where implant removal is approximately in a year or earlier, MS Screws & Plates must be used for easy removal.

- High Torque Advantage: Due to large surface area, high torque can be used while tightening or removing a Non-Locking and Locking Screws.

- Even Titanium Bear High Torque: As Titanium is less harder than SS, 4.5, 3.5, 2.7mm Titanium Screws will be able to bear high torque while tightening or removing a screw from plate/bone.

- Easy Implant Removal Surgery: Due to design supremacy, screws can be removed easily from plates even after 5, 10 or 20 years of the surgery and implant removal surgery will be easy without any risk or refracture.

- Large Diameter Can Bear High Torque: Large diameter screws like 6.5mm or 7.2mm which require high torque for tightening or removing can bear it without becoming head round.

- Cold Welding Solution: Cold Welding in locking screws and plates made with Titanium material is a common problem in revision surgery which can be easily solved with our patented design Plate Cutter.

- Accurate Method Implant Removal: As of today, there is no accurate method to remove a titanium cold-welded screw plate. With our specially designed screws, plates, and Plate Cutter, we provide a definitive solution to remove any screw from any plate, even years after surgery.

What risks are we mitigating by performing this screw removal?

As per Google data, World’s Revision Trauma Surgeries are 15% of total surgeries done in the world. But which 15% patient will come for revision surgeries, nobody knows.

Reason for Revision Surgery:

- In Children implants are mandatory removed within 1 year of the surgery.

- The implant breaks due to fall.

- The patient gets infection.

- The Screw Becomes loose.

- Non-Union of bones takes place.

- Osteoporotic bone.

- In thin patients problem arises due to soft tissue irritation, pain and cosmetic issues.

- Skin Irritation.

- Persistent pain at implant site like elbow, knee and shoulder so implants are removed.

- Sometimes due to non-union implants are removed and bone grafting is done.

- Metal reaction to human body.

- Cold sensitivity in extremities where plates are close to skin.

- In some patients too much load is carried by the implants, that weakens the bone so, implants are removed once healing is complete.

- Joint replacement: If prior fixation is done then implants are removed for joint replacement.

- Elective Surgeries – as some patients request removal once healing is confirmed.

Difficult Trauma Implant Removal Surgery Due To Cold Welding?

Here’s The Solution :- Introducing the Dual-Drive Locking and Non-Locking Screw – a breakthrough in orthopaedic trauma surgery. It is the only screw worldwide that is compatible with two different screwdrivers. If one screwdriver fails during surgery, the second can be immediately used to successfully complete the procedure.

What We Use At Present

Properties:

3.5, 4.5 mm Single Hexagon Head Drive Screw

- It is round from outside and hexagon from inside.

Single Drive

- It has just single drive that is hexagon from inside.

Disadvantage

- The contact surface of one side of hexagon and screw driver is just 2.02mm.

- It can bear less torque and while tightening or removing a screw from bone and fails easily because of less contact area and inner hexagon becomes round.

- The screw can be tighten or can be removed from just one internal hexagon.

- More chances of failure when screw is small in size i.e. 3.5mm Screw and contact surface is just 1.44mm.

- Titanium is softer than S.S. So due to low contact area more chances of failure.

What We Will Use Tomorrow

Properties:

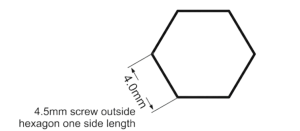

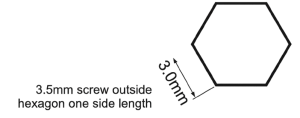

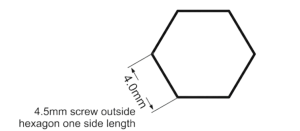

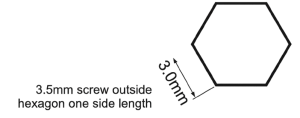

3.5, 4.5 mm Dual Hexagon Head Drive Screw

- It is hexagon from outside and hexagon from inside.

Double Drive

- It has double drive i.e. outside hexagon from inside.

Advantage

- The contact surface of one side of hexagon and screw driver is 4.0mm.

- It can bear more torque while tightening and removing a screw from a bone and less chances of becoming outer hexagon round.

- The screw can be tighten or removed by two . i.e. internal as well as external hexagon.

- Less chances of failure when screw is small in size i.e. 3.5mm screw and contact surface is 3.0mm of outer Hex.

- Titanium is softer than S.S., so less chances of failure due to more contact area.

NON LOCKING BONE SCREW REINVENTED

What We Use At Present

Properties:

3.5, 4.5 mm Single Hexagon Head Drive Screw

- It is round from outside and hexagon from inside.

Single Drive

- It has just single drive that is hexagon from inside.

Disadvantage

- The contact surface of one side of hexagon and screw driver is just 2.02mm.

- It can bear less torque and while tightening or removing a screw from bone and fails easily because of less contact area and inner hexagon becomes round.

- The screw can be tighten or can be removed from just one internal hexagon.

- More chances of failure when screw is small in size i.e. 3.5mm Screw and contact surface is just 1.44mm.

- Titanium is softer than S.S. So due to low contact area more chances of failure.

What We Will Use Tomorrow

Properties:

3.5, 4.5 mm Dual Hexagon Head Drive Screw

- It is hexagon from outside and hexagon from inside.

Double Drive

- It has double drive i.e. outside hexagon from inside.

Advantage

- The contact surface of one side of hexagon and screw driver is 4.0mm.

- It can bear more torque while tightening and removing a screw from a bone and less chances of becoming outer hexagon round.

- The screw can be tighten or removed by two . i.e. internal as well as external hexagon.

- Less chances of failure when screw is small in size i.e. 3.5mm screw and contact surface is 3.0mm of outer Hex.

- Titanium is softer than S.S., so less chances of failure due to more contact area.

LOCKING BONE SCREW REINVENTED

OLD DESIGN LOCKING SCREW

Disadvantage(5.0mm)

- Single Hexagon Drive Screw

- It is round from outside and Hexagon from Inside

- 5.0mm Screw inside hexagon one side length

Disadvantage(3.5mm)

- The contact surface of one side of hexagon and screw driver is just 2.02mm

- It can bear less torque while tightening or removing screw a screw from bone/plate and fails easily because of less contact are and inner hexagon becomes round

- More chances of failure when screw is small in size i.e. 3.5mm screw and contact surface is just 1.44mm

- Titanium is softer than SS so due to low contact area more chances of failure.

NEW DESIGN LOCKING SCREW

Advantage

- 5.0mm Triangular Hexagonal Double Drive Screw

- It has double drive i.e. inside Hexagonal drive and outside Triangular Drive.

- 5.0mm screw outside triangular one side length.

Advantage

- The contact surface of one side of Triangular is 6.42mm

- It can bear more torque while tightening or removing a screw from bone/plate and negligible chances of becoming outer Triangular shape round.

- Less chances of failure when screw is small in size i.e. 3.5mm and contact surface is 4.76mm of out Triangular design.

- Titanium is softer than SS, so less chances of failure due to more contact area.